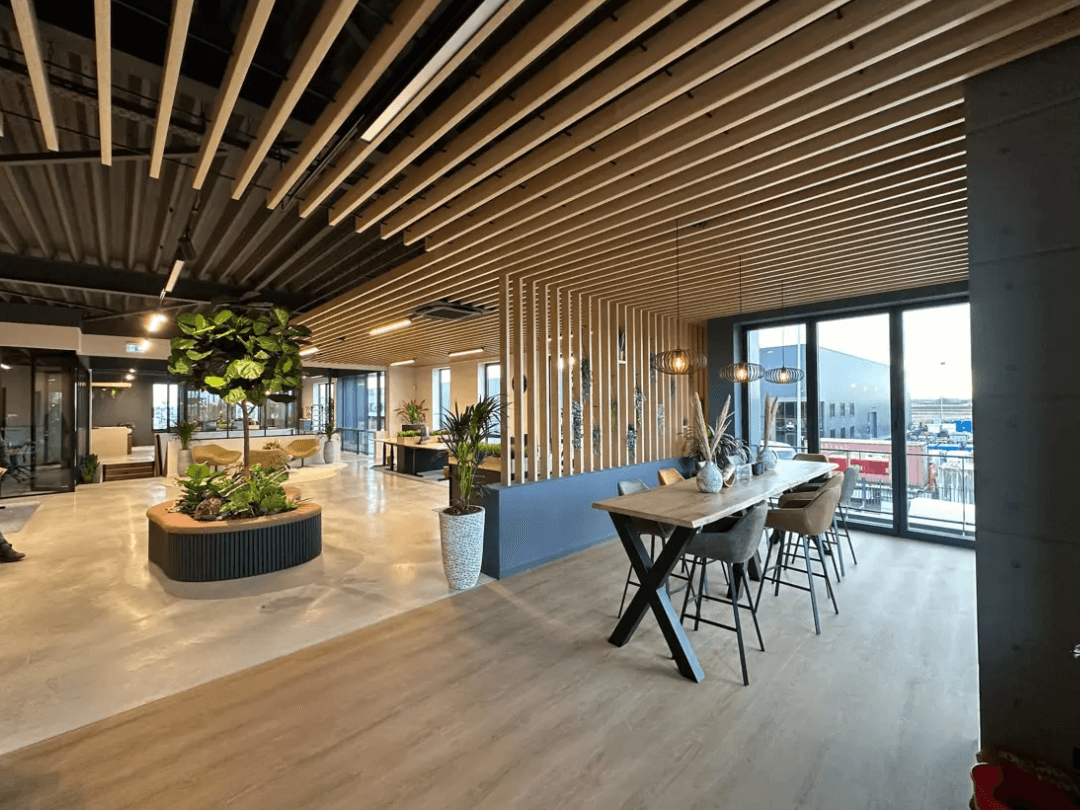

New Océ Technologies headquarters in Venlo

For the new headquarters of Océ Technologies in Venlo, interior builder Gepla B.V. from Elsloo was looking for a good solution for the ceiling and wall finishing. A staggering 55,000 linear metres of wooden laths, in long lengths, were needed for this project. Shortened lengths, mitre-cut lengths and butt veneer glued lengths were also needed for the realisation.

The advice

Our Sales Manager Michel advised Karel Olfers (project leader of Gepla) to choose MDF, sheathed with veneer. Working with wood often causes problems. Wood is full of tension, it shrinks and expands. Especially on a construction site, where moisture always plays a role. Long lengths of wood tend to warp. But luckily, you can make veneer from any type of wood. MDF does not warp and the veneer coating gives the product the full appearance of wood. To convince the architect of the construction project of the advantages of Wiggers, we had a number of rules drawn up. No small samples, but simply in the required long formats. This gives the customer a true idea of what it will be like! "We chose Wiggers' solution because of the quality. There was also a slight price difference, but that wasn't the most important thing. You just have to make sure that the solution is really going to be good. And that's certainly the case", says Tom Kitzen, planner at Gepla.

The realisation

Wiggers made and delivered the desired laths, which have exactly the desired appearance. They are also water-repellent thanks to the varnish finish. The project went smoothly. There was contact almost daily between Tom van Gepla and Sander Jansen, the planner of Wiggers. "Because we tend to work project-driven, not product-driven. The market demands flexibility and that's what we offer", says Sander.

The power of Wiggers

Thanks an excellent collaboration with our customers, we know and understand your challenges. This enables us to deliver solutions that perfectly match your needs and projects. Always ready for installation. Because we have moved the work from the construction site to our factory. This saves production steps, manpower and waste on location.