Customisation and EcoProfiel for major maintenance projects

A major maintenance project is taking place in the Overvecht district (Utrecht). Kooistra Geveltechniek BV has been commissioned to renew, among other things, the window frames of the 1,800 homes, spread over 10-storey flats. Bauke Meijer, site manager at Kooistra: "We've already worked on projects with Wiggers several times. We were pleased with both the materials and their service. It goes without saying that we approached Wiggers again for this project."

Matching products and finishing

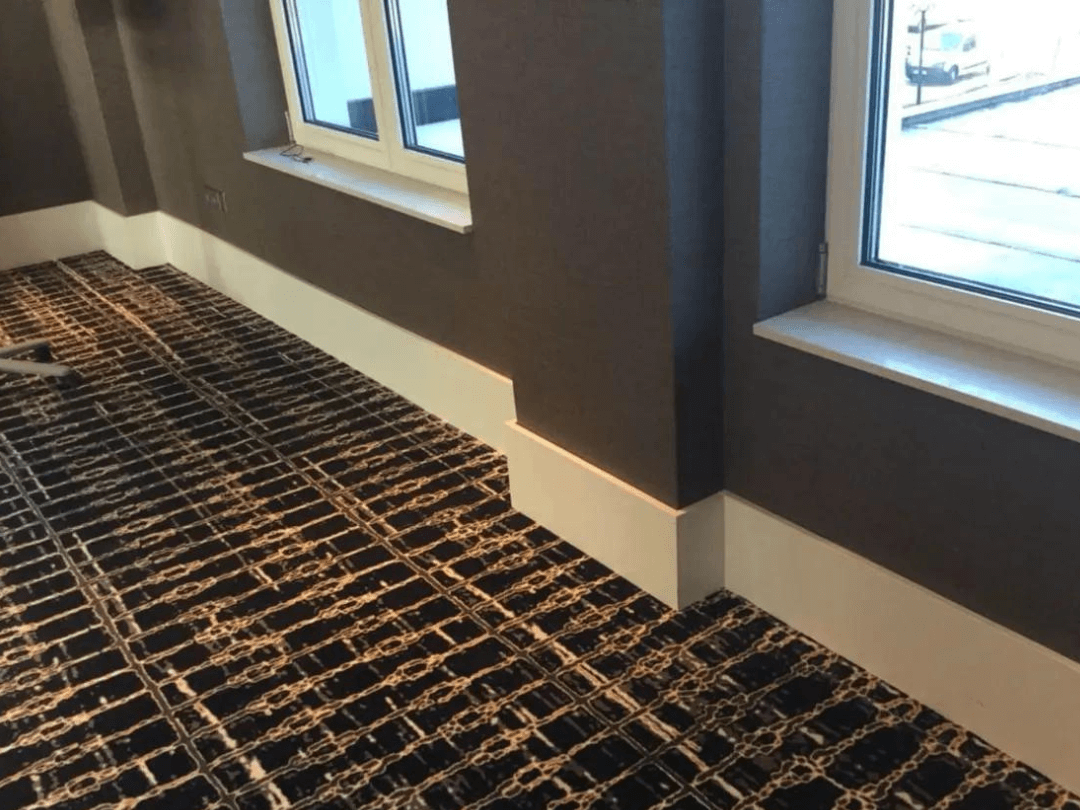

Thanks to his experience and previous collaborations with Wiggers, Bauke knows exactly which products and finishes he needs: "For the windowsills I opted for a P5 Superpan with PVC foil. This reduces the risk of damage and it gives the windowsills a long lifespan." In addition, we also used many products from the EcoProfiel range, such as architraves and corners, as well as skirting boards. Bauke Meijer: "I always have the information about the EcoProfiel range at hand. Because the products are in stock, I can switch and order quickly. But they also act fast if you have a customisation request. Their employees are happy to help you choose the right product."

Fast delivery

Our co-creators fill a container with products. This is then transported to the construction site. In Utrecht, for example, they currently receive a container full of finished products every three weeks, ready for installation. Bauke Meijer: "Whenever I contact them about products, I always get a work planner on the line quickly, one call is enough and they always think in solutions." The deliveries for this project will continue for a few more months. The result: energy label A for all homes and improved quality of life in the neighbourhood. We are proud to contribute to this with our products!

The power of Wiggers

Thanks an excellent collaboration with our customers, we know and understand your challenges. This enables us to deliver solutions that perfectly match your needs and projects. Always ready for installation. Because we have moved the work from the construction site to our factory. This saves production steps, manpower and waste on location.