Windowsills

Windowsills that leave our factory always have a long lifespan, thanks to the finish with a sturdy top layer. This makes them scratch, impact resistant, moisture and UV resistant. Moreover, no customisation request is too crazy. Once we know all your wishes and requirements, we will develop the perfect windowsill for you in our factory.

Advantages at a glance

- Delivery per room

- Strong coupling with dowel connection

- All profiles possible

Windowsills that you can install immediately

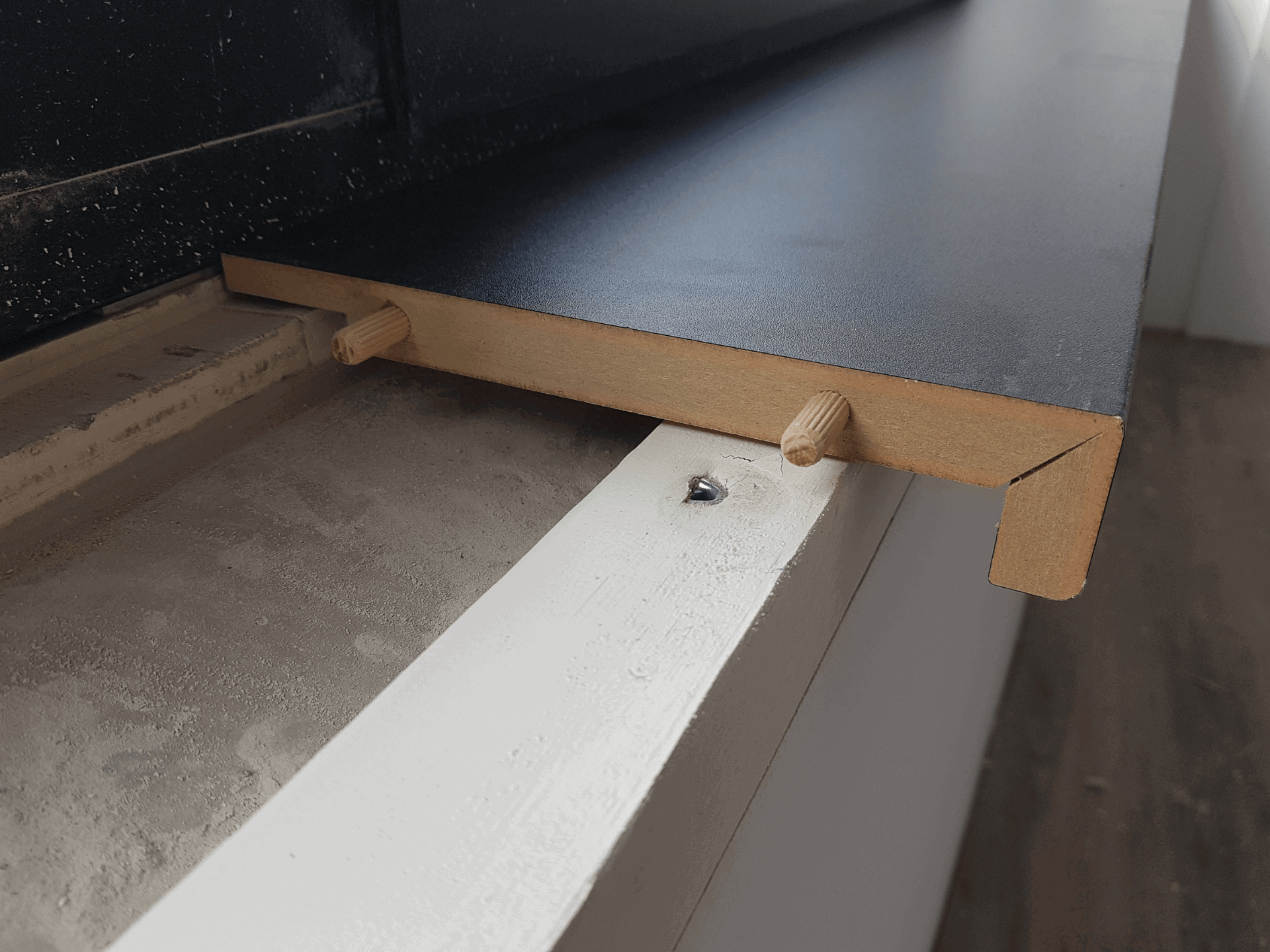

All windowsills that leave Wiggers can be installed immediately. If desired, we can provide them with dowels, which helps reduce installation time.

Thanks to this prefabricated delivery, all you have to do is install our windowsills on site.

Delivery per room

We supply prefabricated windowsills per floor and room, for both small and large-scale projects. This way, the windowsills will be on the right floor and in the right room quickly.

Strong coupling with dowel connection

Connect the windowsills infinitely using our sturdy dowel connections. This makes on-site installation even easier.

All profiles possible

In addition to a standard windowsill profile, customisation is our specialty. Everything is possible: narrow, sloping or even round.

All specifications

| Application area | Interior |

| Most frequently used base material | MDF V313 or P5 chipboard carrier |

| Most frequently used finishing | Solid top layer, PU glued (waterproof) |

| Depth | 200/250/300/350/400 mm or on request |

| Length | 3050/4880 mm |

| Nose height | 34 mm |

| Scratch-resistant | Yes |

| Impact-resistant | Yes |

| Moisture-resistant | Yes |

| UV-resistant | Yes |

| Painting needed | No |

| Fire retardent | Optional |

| FSC Quality label | Yes |

Casing profiles for the construction industry

Our stock range of casing profiles is fully focused on construction. Complete, yet flexible and customer-specific. The profiles are ready-to-use, sustainable products for construction. Examples include reveal trim, pipe ducts, skirting boards and windowsills.