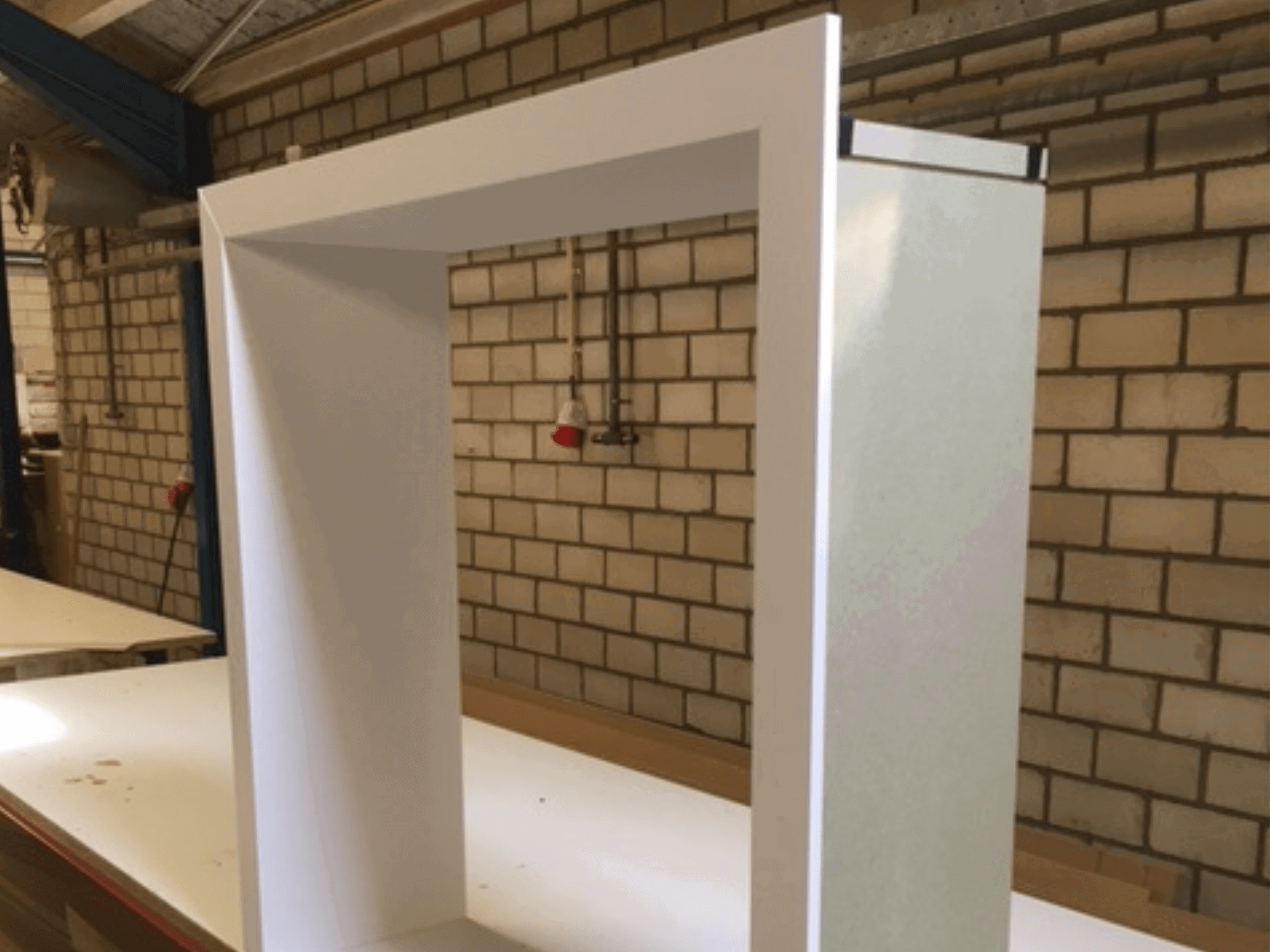

Window frame casing

We deliver the window frame casing as a complete prefabricated package. The windowsills, reveals, architraves and mounting materials. All elements consist of a base material (often V313 MDF) and a top layer in the desired final colour. This allows installation to be carried out by one person. This makes our window frame casing an excellent solution for renovation projects or construction projects in both residential and commercial construction.

Advantages at a glance

- Delivery per room

- Quick to assemble

- Long lifespan

Speed with ready-made window frame casing

With the traditional method, casing the window frames takes an average of 2 to 3 man-days per home. The finishing material still needs to be cut to size and after installation, a painter will come by for the final finishing touches.

Wiggers' prefabricated window frame casing packages are already custom-made and don't need to be painted. This not only saves time on location, but also ensures lower costs and little inconvenience for local residents.

Delivery per room

We deliver the window frame casing as a complete prefabricated package. We pack these packages per floor and room, so logistics on location run smoothly.

Quick to install

We provide the window frame casing in our factory with the correct dimensions and the desired finish. This means that installation is the only thing that's required on location. This not only saves manpower during the installation phase, but also a lot of time.

Long lifespan

Our window frame casing has a long lifespan. This is due to the combination of an MDF base and the finish with a sturdy top layer. This makes the window frames scratch and impact resistant and resistant to discolouration due to sunlight.

All specifications

| Application area | Interior |

| Most frequently used base material | MDF V313 or P5 chipboard carrier |

| Most frequently used finishing | Solid top layer, PU glued (waterproof) |

| Depth | 200/250/300/350/400 mm or on request |

| Length | 3050/4880 mm |

| Nose height | 34 mm |

| Scratch-resistant | Yes |

| Impact-resistant | Yes |

| Moisture-resistant | Yes |

| UV-resistant | Yes |

| Painting needed | No |

| Fire retardent | Optional |

| FSC Quality label | Yes |

Reference 't Harde

To ensure an energy-efficient future, 30 homes in 't Harde have been renovated by construction company Salverda. RC Panels supplies new façades for this project. Wiggers took care of the window frame casing. The goal was to install these quickly with little waste. Together with DIB Geveltechniek and RC Panels, we looked for the best solution. Watch the video to see how we did this.

Casing profiles for the construction industry

Our stock range of casing profiles is fully focused on construction. Complete, yet flexible and customer-specific. The profiles are ready-to-use, sustainable products for construction. Examples include reveal trim, pipe ducts, skirting boards and windowsills.